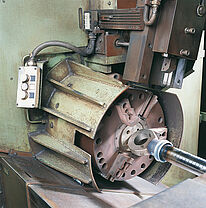

Of two components to be connected, the part clamped spindle-sided into the machine is set into rotation and the part held in the sled clamping unit is beared against with defined pressure (friction force). The relative movement (rotation) and the simultaneously applied pressure lead to heating of the components’ contact surfaces. Through heat conduction, the temperature is equalized over the entire contact surface in a very short time.

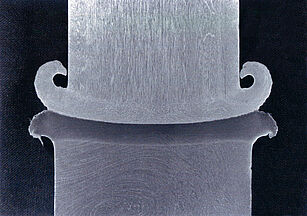

After rotation has been terminated, the pressure is increased again (the so-called upsetting), whereby the plasticized material is pressed outward. A bead formation, a characteristic of friction welding, is created. Friction welding demonstrates decisive advantages compared to other welding processes, including:

- Short welding times

- Pore-free weld connections

- Excellent weld quality

- No additional welding materials

We would be glad to carry out a test weld for you.