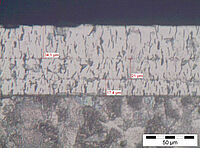

3-Layer chrome plating

This process was developed to produce hard chrome layers with very high corrosion resistance.

In 3-layer chrome plating, the surface area to be chrome-plated is initially micro-finished to a roughness of Rz<1.5 µ. Three micro-cracked hard chromium layers are then deposited, whereby a mechanical and chemical intermediate treatment takes place after each layer buildup. In a final step, the sealing of the chrome surface is carried out with a TSI finishing treatment (TSI = Teflonizing). The downstream polishing process smooths the surface, whereby roughness of Rz<1.5 µ or Ra<0.1 µ are possible.

For 3-layer chrome plating, we recommend chrome layer thicknesses of 60 – 80µ. In this process, corrosion resistances > 200 hours in accordance with EN ISO 9227 NSS at a rating of 9.5 – 10 in accordance with EN ISO 10289 are achieved.